Solder Leaded

- Product num. : 600982

- EAN: 4005796186224

- Manufacturer: FELDER

- Manufacturer number: 18600520

-

Show more

-

From 1€19.50*

-

From 10€18.04*

-

From 25€17.16*

-

From 50€15.60*

Available, delivery time: 1-3 days

- Product num. : 601016

- Manufacturer: FELDER

- Manufacturer number: 18600530

-

Show more

-

From 1€32.85*

-

From 10€30.39*

-

From 25€28.91*

-

From 50€26.28*

Available, delivery time: 1-3 days

- Product num. : 600983

- EAN: 4005796186286

- Manufacturer: FELDER

- Manufacturer number: 18600720

-

Show more

-

From 1€14.50*

-

From 10€13.41*

-

From 25€12.76*

-

From 50€11.17*

Available, delivery time: 1-3 days

- Product num. : 600984

- Manufacturer: FELDER

- Manufacturer number: 18600730

-

Show more

-

From 1€25.02*

-

From 10€24.45*

-

From 25€23.20*

-

From 100€20.99*

Currently not available (delivery time on request)

- Product num. : 600979

- EAN: 4005796186019

- Manufacturer: FELDER

- Manufacturer number: 18601020

-

Show more

-

From 1€14.50*

-

From 10€13.41*

-

From 25€12.76*

-

From 50€11.60*

-

From 100€10.64*

Available, delivery time: 1-3 days

- Product num. : 600980

- EAN: 4005796186026

- Manufacturer: FELDER

- Manufacturer number: 18601030

-

Show more

-

From 1€26.00*

-

From 10€24.99*

-

From 25€23.58*

-

From 50€21.99*

-

From 100€20.56*

Available, delivery time: 1-3 days

- Product num. : 600981

- EAN: 4005796186033

- Manufacturer: FELDER

- Manufacturer number: 18601040

-

Show more

-

From 1€50.00*

-

From 10€48.25*

-

From 25€45.50*

-

From 100€41.00*

Available, delivery time: 1-3 days

- Product num. : 600974

- Manufacturer: FELDER

- Manufacturer number: 18640720

-

Show more

-

From 1€16.40*

-

From 10€15.80*

-

From 25€14.20*

-

From 50€13.50*

-

From 100€12.36*

Available, delivery time: 1-3 days

- Product num. : 600975

- Manufacturer: FELDER

- Manufacturer number: 18640730

-

Show more

-

From 1€32.50*

-

From 10€30.06*

-

From 25€28.60*

-

From 50€26.00*

-

From 100€23.88*

Available, delivery time: 1-3 days

- Product num. : 600976

- EAN: 4005796186514

- Manufacturer: FELDER

- Manufacturer number: 18640740

-

Show more

-

From 1€67.50*

-

From 10€62.44*

-

From 25€59.40*

-

From 50€54.00*

-

From 100€49.98*

Available, delivery time: 1-3 days

- Product num. : 601022

- EAN: 4005796186439

- Manufacturer: FELDER

- Manufacturer number: 18641020

-

Show more

-

From 1€14.65*

-

From 10€13.55*

-

From 25€12.89*

-

From 50€11.72*

Available, delivery time: 1-3 days

- Product num. : 600977

- EAN: 4005796186521

- Manufacturer: FELDER

- Manufacturer number: 18641520

-

Show more

-

From 1€14.50*

-

From 10€13.80*

-

From 25€12.80*

-

From 50€11.50*

-

From 100€10.80*

Currently not available (delivery time on request)

- Product num. : 600978

- Manufacturer: FELDER

- Manufacturer number: 18641530

-

Show more

-

From 1€28.00*

-

From 10€25.90*

-

From 25€24.64*

-

From 50€22.40*

Available, delivery time: 1-3 days

Leaded solder: Indispensable for your soldering work

What is leaded solder

Leaded solder is an alloy consisting mainly of tin and lead. This alloy is characterized by its low melting point and excellent adhesion, which makes it particularly suitable for various soldering tasks. The typical composition is 60% tin and 40% lead, although other ratios are also possible. Thanks to the addition of lead, the solder offers good flow properties and ensures robust and durable solder joints.

Advantages of leaded solder

One of the main advantages of leaded solder is its low melting temperature, which is usually between 180°C and 190°C. This means that less energy is required for heating and sensitive electronic components are protected. The lead also allows the tin to be distributed evenly, which leads to better wetting and more stable connections. Another advantage is the high strength of the soldered connections, which are characterized by their durability and reliability.

Lead solder is also characterized by its good electrical conductivity. This makes it particularly suitable for applications where a reliable electrical connection is required. This includes the repair and manufacture of printed circuit boards as well as various applications in the electronics industry.

Application areas for leaded solder

Lead solder is often used in the electronics and electrical industry, particularly for the production of printed circuit boards and the assembly of electronic components. Its excellent flow properties and low melting temperature make it ideal for the construction of complex circuits and sensitive devices

Lead solder also plays an important role in precision mechanics and model making. Small and precise solder joints are often required here, which are optimally fulfilled by the properties of leaded solder. It is also used in jewelry manufacturing and in the repair of musical instruments, where a high degree of precision and accuracy is required.

Safety and environmental guidelines

When working with leaded solder, special care must be taken as the lead it contains is toxic and can release harmful vapors. It is recommended to always solder in well-ventilated areas and to wear suitable protective equipment such as respirators and gloves. In addition, contact with the skin should be avoided and rooms should be cleaned thoroughly after finishing work.

Due to the toxic properties of lead, there are strict environmental regulations in many countries that restrict or even prohibit the use of leaded solder. European directives such as the RoHS regulation (Restriction of Hazardous Substances), for example, prohibit the use of lead in electronics production. It is therefore important to find out about the applicable laws before use and to use lead-free alternatives if necessary. Leaded solder can only be supplied to commercial customers (proof of trade required with initial order).

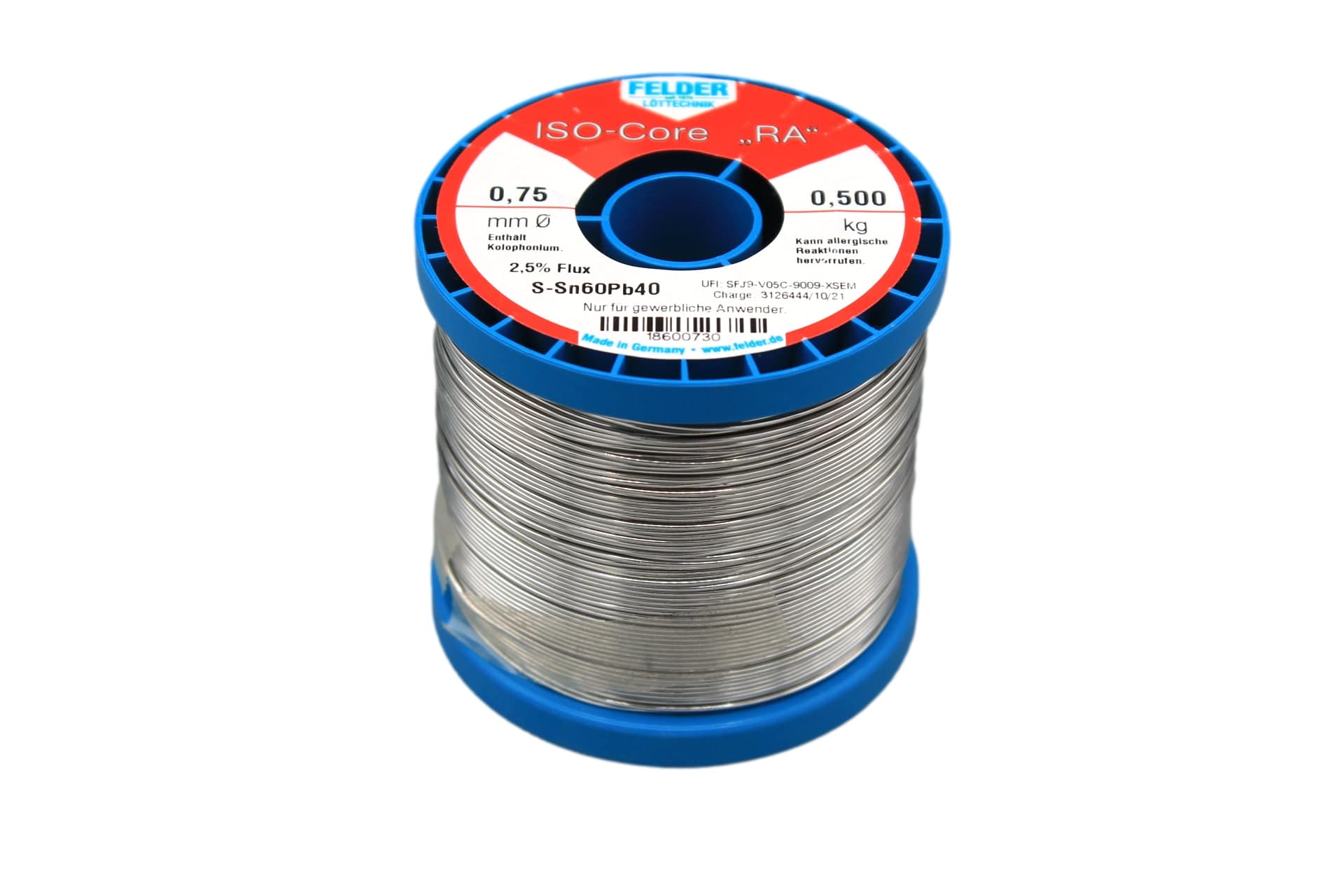

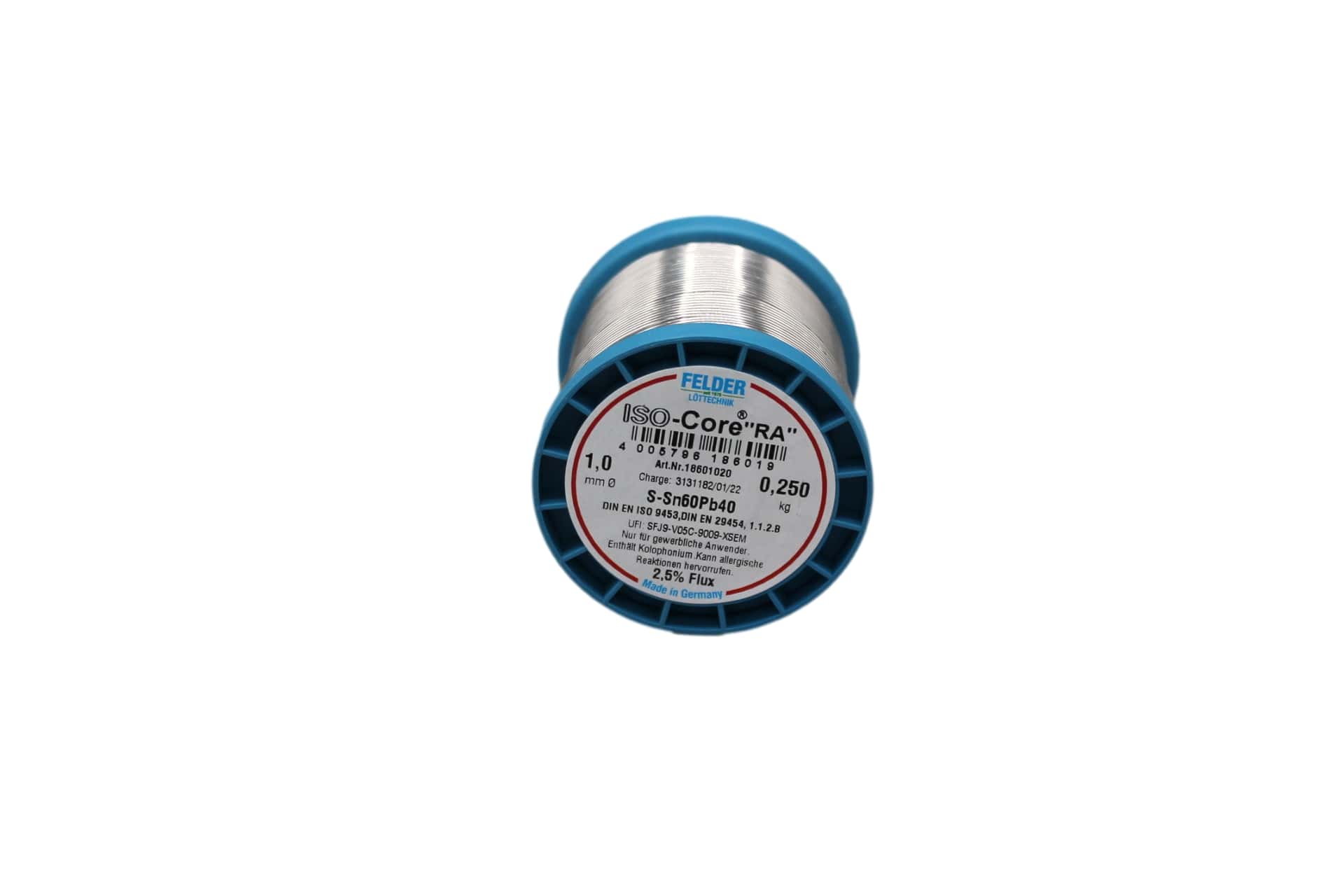

Available shapes and sizes

Leaded solder is available in various shapes and sizes to meet the different requirements of users. It is available in wire form on rolls, as bars or in granulate form. The wire thicknesses vary from very thin wires for precise work to thicker wires for larger solder joints. Depending on the application, users can select the most suitable shape and size for them.

Larger quantities and special compositions are also available for industrial use. This can be solder with a flux core, for example, which makes soldering easier and enables a clean, fast connection. This flux helps to remove oxides and ensures better adhesion of the solder to the components.

Tips for handling leaded solder

To achieve optimum results, you should follow a few basic tips when working with leaded solder. Make sure that the solder joints are clean and free of impurities to ensure good adhesion. Use a soldering iron with a suitable tip, selected according to the size of the soldered joints. Make sure to hold the soldering iron against the soldering point just long enough for the solder to flow to avoid overheating and damage to the components.

After soldering, the connections should be thoroughly checked for cold welds and other defects. Clean your tools after completing the soldering work to extend their service life and ensure a continuous quality of work.

Please note that leaded solder may only be sold to commercial customers. We always require a valid proof of trade (VAT number or trade license) for the first order.