Solder Leadfree

- Product num. : 600985

- Manufacturer: FELDER

- Manufacturer number: 20960520

-

Show more

-

From 1€33.18*

-

From 10€30.69*

-

From 25€29.20*

Currently not available (delivery time on request)

- Product num. : 600986

- EAN: 4005796209626

- Manufacturer: FELDER

- Manufacturer number: 20961020

-

Show more

-

From 1€28.50*

-

From 10€26.36*

-

From 25€25.08*

-

From 100€24.31*

Currently not available (delivery time on request)

- Product num. : 600987

- EAN: 4005796520028

- Manufacturer: FELDER

- Manufacturer number: 52760520

-

Show more

-

From 1€40.00*

-

From 10€38.00*

-

From 25€33.50*

Available, delivery time: 1-3 days

- Product num. : 600988

- EAN: 4005796520066

- Manufacturer: FELDER

- Manufacturer number: 52761020

-

Show more

-

From 1€26.75*

-

From 10€24.74*

-

From 25€23.69*

Available, delivery time: 1-3 days

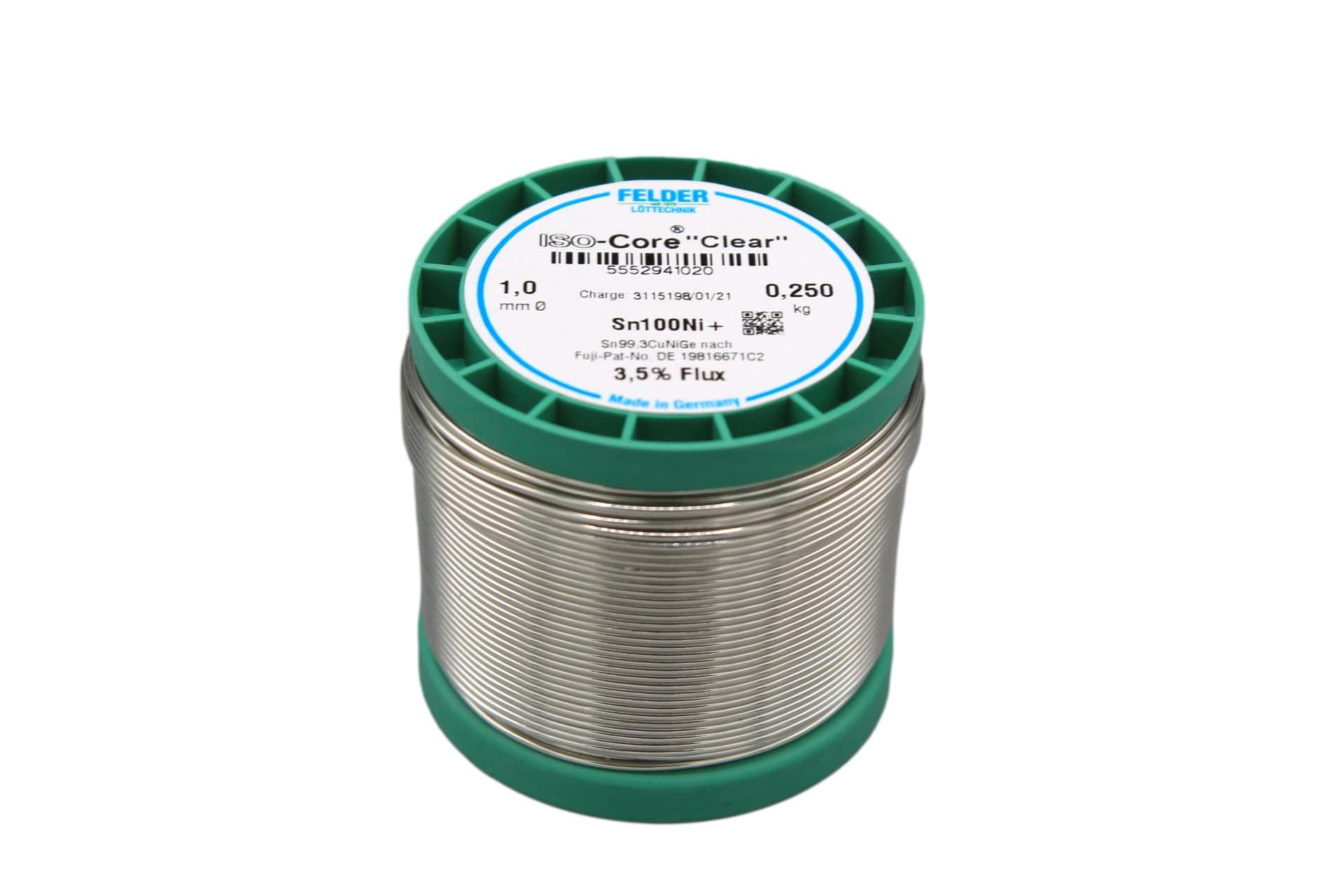

- Product num. : 601004

- Manufacturer: FELDER

- Manufacturer number: 5552941020

-

Show more

-

From 1€16.85*

-

From 10€15.59*

-

From 25€14.83*

-

From 50€13.48*

-

From 100€10.95*

Currently not available (delivery time on request)

- Product num. : 600846

- EAN: 4260766890796

- Manufacturer: Zhongdi

- Manufacturer number: ZD-160

-

Show more

-

From 1€1.50*

-

From 10€1.39*

-

From 25€1.31*

-

From 50€1.20*

-

From 100€1.05*

Available, delivery time: 1-3 days

Lead-free solder - Environmentally friendly and safe solution for your soldering projects

Introduction to lead-free solder

Lead-free solder is an environmentally friendly alternative to traditional leaded solder. It is mainly used in the electronics industry, as legal regulations and environmentally conscious decisions restrict the use of lead. Lead-free solder offers many advantages, including improved safety and reduced environmental impact. The following text aims to provide you with a comprehensive overview of the different types, applications and benefits of lead-free solder.

Types of lead-free solder

There are several types of lead-free solder, which differ mainly in their alloy composition. The most common alloys consist of tin (Sn) and vary by admixtures of copper (Cu), silver (Ag) and other metals. For example, the alloys Sn96.5/Ag3.0/Cu0.5 (also known as SAC305) and Sn99.3/Cu0.7 are widely used. Each alloy has specific properties that make them suitable for different applications and requirements.

Choosing the right alloy depends on various factors, including processing temperature, flux types and mechanical properties. It is important to get detailed information about which type is most suitable for your specific project.

Advantages of lead-free solder

Probably the most significant advantage of lead-free solder is its environmental friendliness. As it contains no lead, the impact on the environment is significantly reduced. This is particularly important when disposing of electronic waste. In addition, lead-free solder offers health benefits as exposure to toxic lead during soldering is eliminated.

Another advantage is the higher resistance to mechanical stress and heat. Many lead-free solders have a higher melting temperature compared to lead-containing alternatives, which makes them more robust and durable in certain applications.

Uses and applications

Lead-free solder is often used in electronics manufacturing and repair. As electrical and electronic devices become smaller and more powerful, smaller and more precise solder joints are required. Lead-free solder is ideal for such applications as it provides a stable and durable connection.

Lead-free solder is also used in the automotive industry, the solar industry and in the manufacture of medical devices. In each of these areas, reliability and ecological compatibility play a crucial role.

Processing and handling

The processing of lead-free solder requires special tools and techniques due to the higher melting temperature. It is recommended to use powerful soldering stations and suitable soldering tips to achieve optimum results. The right flux is also crucial as it improves the wetting properties and flow of the solder.

When handling, ensure that the working environment is well ventilated to minimize the release of fumes. Protective clothing and goggles also contribute to safety.

Tips for choosing the right lead-free solder

When choosing the right lead-free solder, you should first consider the requirements of your project. Think about factors such as melting point, mechanical strength and electrical conductivity. A commonly used solder in electronics manufacturing is SAC305, for example, because it offers a good balance of these properties.

It is also advisable to follow the manufacturer's recommendations and, if necessary, carry out test runs to check the performance of the solder in your specific application. Finally, always keep in mind the environmental and health benefits that lead-free solder offers.

Important considerations for switching to lead-free solder

Switching from leaded to lead-free solder sometimes requires adjustments to production processes and training for personnel. It is important to find out about the legal regulations in your region, as these often stipulate the use of lead-free materials. Companies that switch to lead-free solder can also often benefit from a better image and greater market opportunities, as they position themselves as environmentally conscious and future-oriented.

Conclusion

Lead-free solder is an advanced, environmentally friendly alternative to conventional lead-based solders. It offers numerous advantages, from improved safety and reduced environmental impact to higher mechanical strength. Choosing the right lead-free solder depends on the specific requirements of your project, and it is important to research the options thoroughly.

With the increasing importance of sustainable practices in the electronics industry and beyond, the use of lead-free solder is a step in the right direction that not only professionals but also hobbyists should consider.