Solder

- Power Supply

- Active Components

- Samwha Capacitors

- Workshop and Soldering Equipment

- Measurement and Testing Equipment

- Remote Controls

- Residual Current / Circuit Breaker

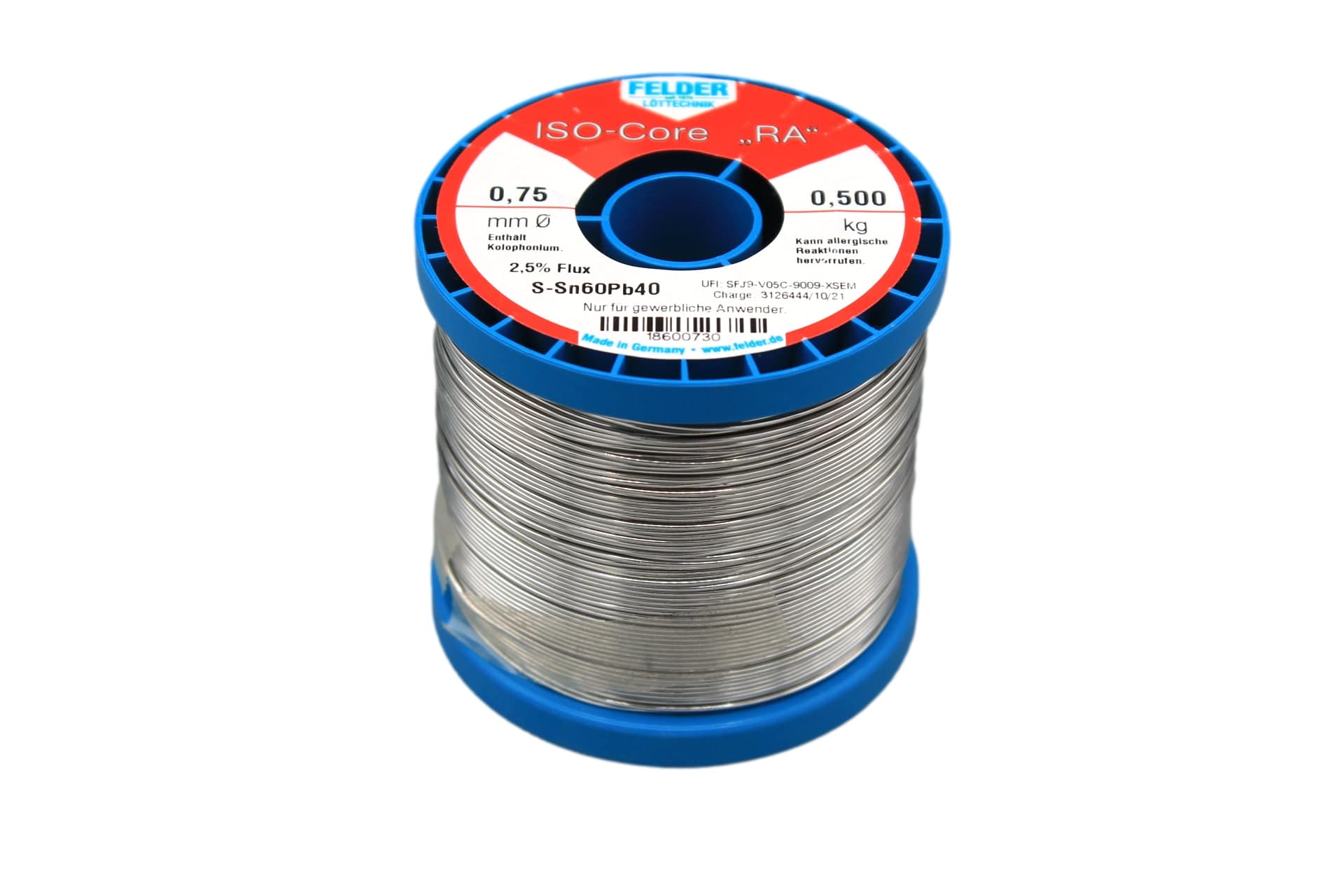

- Product num. : 600982

- EAN: 4005796186224

- Manufacturer: FELDER

- Manufacturer number: 18600520

-

Show more

-

From 1€19.50*

-

From 10€18.04*

-

From 25€17.16*

-

From 50€15.60*

Available, delivery time: 1-3 days

- Product num. : 601016

- Manufacturer: FELDER

- Manufacturer number: 18600530

-

Show more

Available, delivery time: 1-3 days

- Product num. : 600983

- EAN: 4005796186286

- Manufacturer: FELDER

- Manufacturer number: 18600720

-

Show more

Available, delivery time: 1-3 days

- Product num. : 600984

- Manufacturer: FELDER

- Manufacturer number: 18600730

-

Show more

-

From 1€33.99*

-

From 10€31.99*

Available, delivery time: 1-3 days

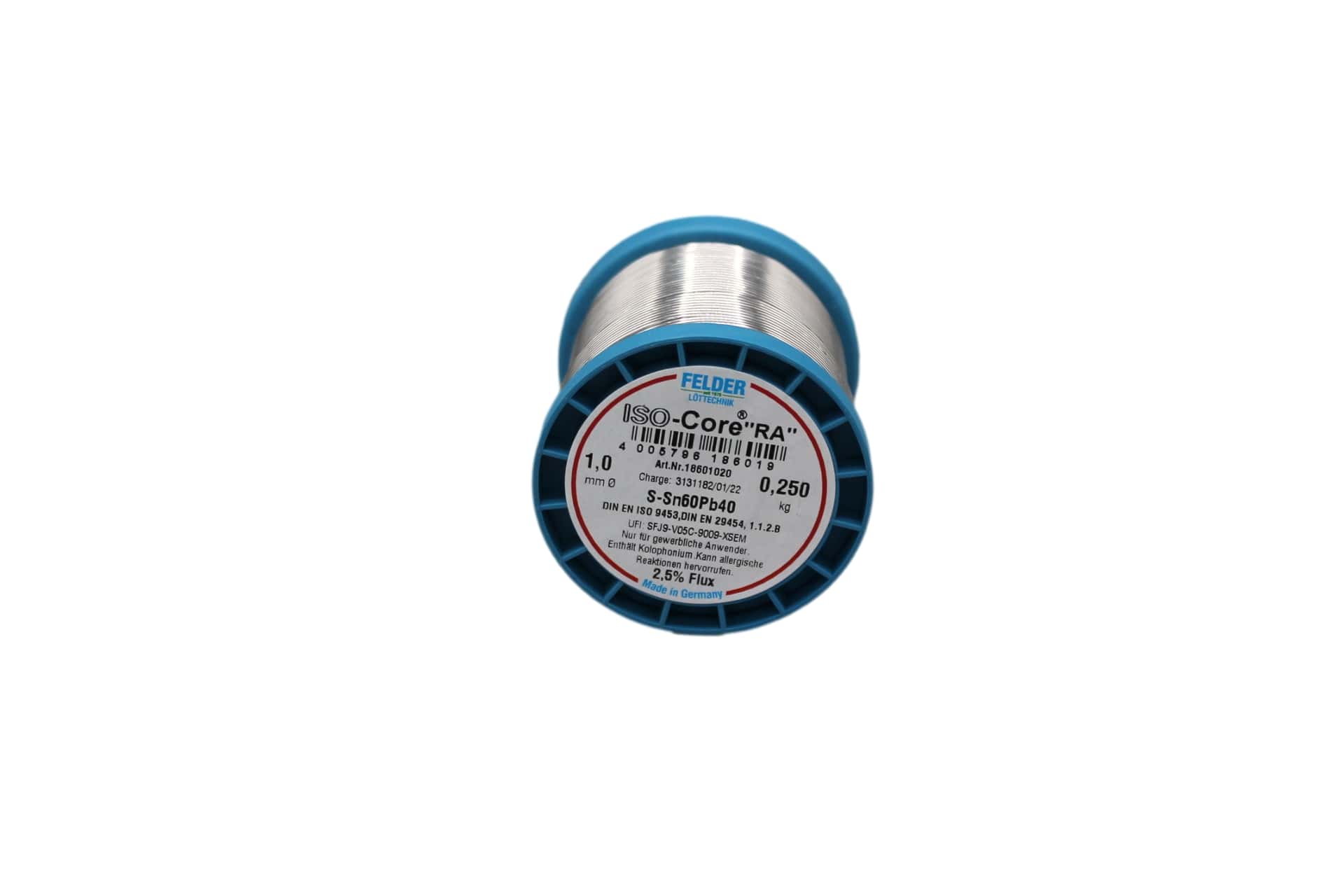

- Product num. : 600979

- EAN: 4005796186019

- Manufacturer: FELDER

- Manufacturer number: 18601020

-

Show more

-

From 1€14.50*

-

From 25€13.41*

Available, delivery time: 1-3 days

- Product num. : 600980

- EAN: 4005796186026

- Manufacturer: FELDER

- Manufacturer number: 18601030

-

Show more

-

From 1€28.00*

-

From 25€25.99*

-

From 50€23.00*

Available, delivery time: 1-3 days

- Product num. : 600981

- EAN: 4005796186033

- Manufacturer: FELDER

- Manufacturer number: 18601040

-

Show more

-

From 1€50.00*

-

From 10€48.25*

-

From 25€45.50*

-

From 100€41.00*

Available, delivery time: 1-3 days

- Product num. : 600974

- Manufacturer: FELDER

- Manufacturer number: 18640720

-

Show more

-

From 1€16.40*

-

From 10€15.80*

-

From 25€14.20*

-

From 50€13.50*

-

From 100€12.36*

Available, delivery time: 1-3 days

- Product num. : 600975

- Manufacturer: FELDER

- Manufacturer number: 18640730

-

Show more

-

From 1€32.50*

-

From 10€30.06*

-

From 25€28.60*

-

From 50€26.00*

-

From 100€23.88*

Available, delivery time: 1-3 days

- Product num. : 600976

- EAN: 4005796186514

- Manufacturer: FELDER

- Manufacturer number: 18640740

-

Show more

-

From 1€67.50*

-

From 10€62.44*

-

From 25€59.40*

-

From 50€54.00*

-

From 100€49.98*

Currently not available (delivery time on request)

- Product num. : 601022

- EAN: 4005796186439

- Manufacturer: FELDER

- Manufacturer number: 18641020

-

Show more

-

From 1€17.49*

-

From 50€13.55*

Available, delivery time: 1-3 days

- Product num. : 600977

- EAN: 4005796186521

- Manufacturer: FELDER

- Manufacturer number: 18641520

-

Show more

-

From 1€14.50*

-

From 10€13.80*

-

From 25€12.80*

-

From 50€11.50*

-

From 100€10.80*

Available, delivery time: 1-3 days

- Product num. : 600978

- Manufacturer: FELDER

- Manufacturer number: 18641530

-

Show more

-

From 1€28.00*

-

From 10€25.90*

-

From 25€24.64*

-

From 50€22.40*

Available, delivery time: 1-3 days

- Product num. : 600985

- Manufacturer: FELDER

- Manufacturer number: 20960520

-

Show more

-

From 1€39.92*

-

From 10€37.00*

Available, delivery time: 1-3 days

- Product num. : 600986

- EAN: 4005796209626

- Manufacturer: FELDER

- Manufacturer number: 20961020

-

Show more

-

From 1€35.00*

-

From 10€33.00*

-

From 100€30.00*

Available, delivery time: 1-3 days

- Product num. : 600987

- EAN: 4005796520028

- Manufacturer: FELDER

- Manufacturer number: 52760520

-

Show more

-

From 1€35.88*

-

From 25€32.50*

Available, delivery time: 1-3 days

- Product num. : 600988

- EAN: 4005796520066

- Manufacturer: FELDER

- Manufacturer number: 52761020

-

Show more

Available, delivery time: 1-3 days

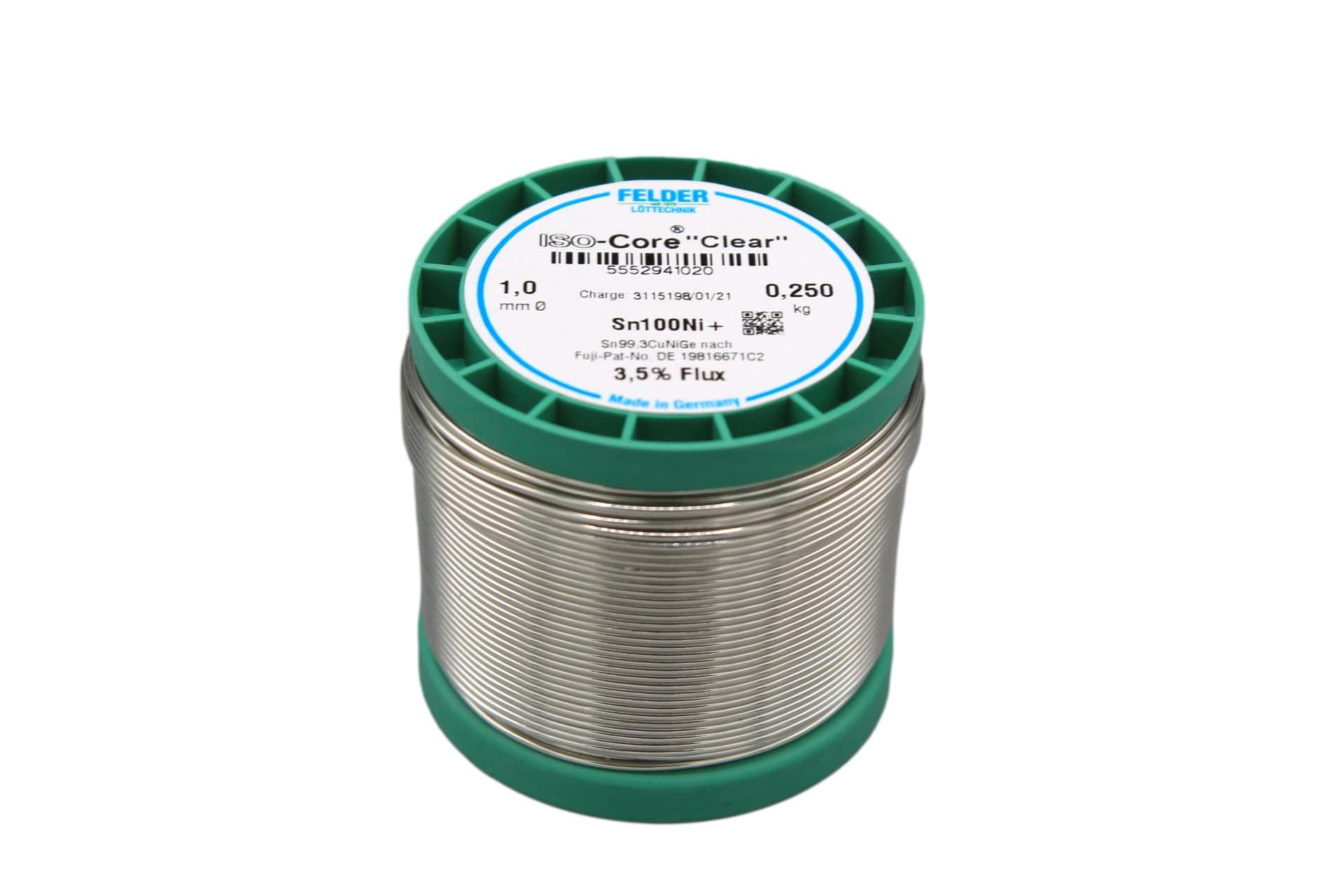

- Product num. : 601004

- Manufacturer: FELDER

- Manufacturer number: 5552941020

-

Show more

-

From 1€16.85*

-

From 10€15.59*

-

From 25€14.83*

-

From 50€13.48*

-

From 100€10.95*

Currently not available (delivery time on request)

- Product num. : 600846

- EAN: 4260766890796

- Manufacturer: Zhongdi

- Manufacturer number: ZD-160

-

Show more

-

From 1€1.51*

-

From 10€1.39*

-

From 25€1.31*

-

From 50€1.20*

-

From 100€1.05*

Available, delivery time: 1-3 days

Solder for all your soldering projects

What is solder

Solder is an essential component in the field of electronics and metalworking. It is a metal alloy that is used to join two or more metal parts. When heated, the solder melts and flows into the joint between the parts, creating a strong, conductive connection. The most common materials for solder are tin and lead, although there are also lead-free alternatives consisting of a combination of tin, silver and copper.

Types of solder

Choosing the right solder depends on the specific requirements of your project. There are different types of solder developed for different applications. Traditional leaded solder consists of a mixture of tin and lead, often in a ratio of 60/40 or 63/37. This alloy melts at relatively low temperatures and is therefore easy to work with.

Lead-free solder is becoming increasingly important as it is more environmentally friendly and safer for health. It usually consists of tin, copper and silver. However, lead-free solder has a higher melting point, which makes it more difficult to process.

Application areas

Solder is used in a wide range of applications. In electronics, it is used to attach components to printed circuit boards. This can be the case both in the manufacture of new devices and in the repair of damaged devices. A high-quality soldering process is crucial for the optimal functioning of electronic devices.

Solder is also indispensable in metalworking. It is used to join metal parts in a wide range of industrial and craft applications. From forging to precision mechanics, there are numerous uses for solder.

Quality characteristics of solder

When buying solder, you should pay attention to a few quality features. One important criterion is the flux core (also known as rosin core), which is present in many types of solder. The flux helps to remove oxidation on the metal surface and thus enables a better connection. It also reduces the formation of solder beads and ensures even wetting of the surface.

The melting point of the solder is also crucial. A low melting point makes processing easier and reduces the risk of damaging sensitive electronic components due to excessive temperatures.

Environmentally friendly alternatives

With the increasing awareness of environmental protection and health, lead-free solder types have established themselves as environmentally friendly alternatives. These consist of tin alloys with copper, silver or nickel and do not contain any lead. They meet the requirements of the RoHS Directive (Restriction of Hazardous Substances) and are considered less harmful to health.

However, lead-free solder also has its challenges. On the one hand, the melting point is higher, which makes the soldering process more demanding. Secondly, there may be different mechanical properties, which must be taken into account when choosing the right soldering method.

Safety when working with solder

Safety precautions should always be taken when working with solder. In particular, heating solder containing lead can produce toxic fumes that can be inhaled. It is therefore advisable to work in well-ventilated rooms or under an extraction system. Wearing protective gloves and goggles is also recommended.

Caution is also required when disposing of residues and waste. Waste containing lead must be disposed of in accordance with local regulations in order to avoid environmental damage. Lead-free alternatives offer a more environmentally friendly solution here, but should still be handled responsibly.

Tips and tricks for a successful soldering process

A successful soldering process starts with the preparation. Clean the parts to be joined thoroughly to ensure optimum wetting. Use a soldering station with adjustable temperature to set the right heat for the selected solder

Place the soldering tip directly on the joint and add the solder as soon as the parts are sufficiently heated. Make sure that the solder is not applied directly to the soldering tip, but to the material to be joined. This ensures even distribution and a strong connection.

Summary

Solder is an indispensable tool in electronics and metalworking. Whether leaded or lead-free, it offers numerous application possibilities and advantages. Pay attention to quality and safety to achieve optimum results and protect your health. With the right materials and methods, your soldering projects will be successful and sustainable.