Insulation Resistance Testers

- Power Supply

- Active Components

- Samwha Capacitors

- Workshop and Soldering Equipment

-

Measurement and Testing Equipment

- Multimeters

- Clamp Meters

- Voltage Testers

- Environment Measuring Instruments

- Automotive Measurement

- Laboratory Power Supplies

- Oscilloscopes

- Wood Moisture Meters

- RPM Meters

- Earth Resistance Meters

- Capacitance Meters

-

Insulation Resistance Testers

- USB Testers

- Cable Testers

- Wallscanners

- Laser Measuring Instruments

- Measuring Accessories

- Remote Controls

- Residual Current / Circuit Breaker

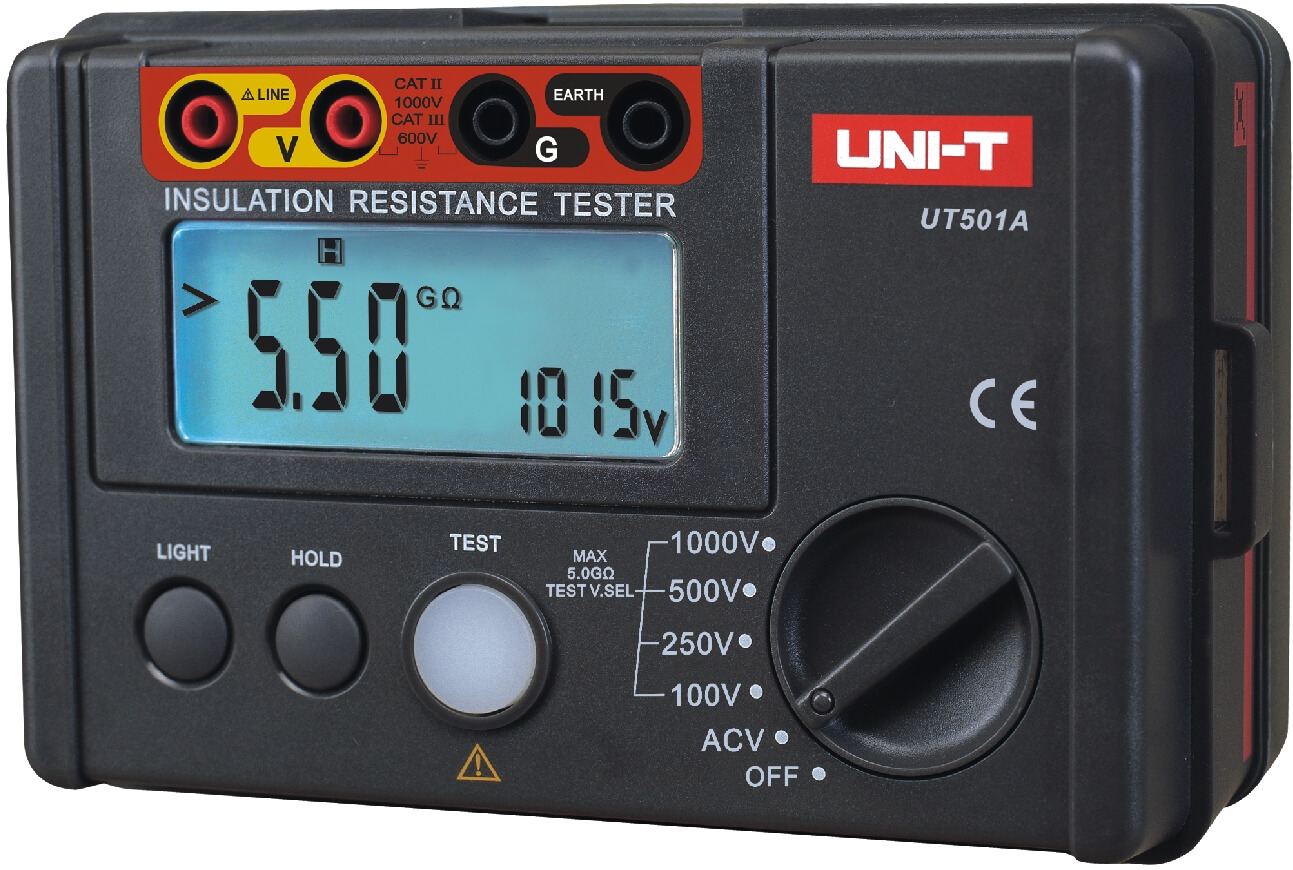

- Product num. : 200376

- EAN: 6935750550113

- Manufacturer: UNI-T

- Manufacturer number: UT501A

-

Show more

-

From 1€60.00*

-

From 5€57.00*

-

From 10€55.20*

-

From 25€52.50*

-

From 50€48.00*

Available, delivery time: 1-3 days

- Product num. : 200377

- EAN: 6935750551103

- Manufacturer: UNI-T

- Manufacturer number: UT511

-

Show more

-

From 1€115.00*

-

From 5€109.25*

-

From 10€105.80*

-

From 25€100.63*

-

From 50€92.00*

Currently not available (delivery time on request)

- Product num. : 202665

- EAN: 6935750505137

- Manufacturer: UNI-T

- Manufacturer number: UT513A

-

Show more

- Product num. : 202628

- EAN: 6935750552605

- Manufacturer: UNI-T

- Manufacturer number: UT526

-

Show more

Available, delivery time: 1-3 days

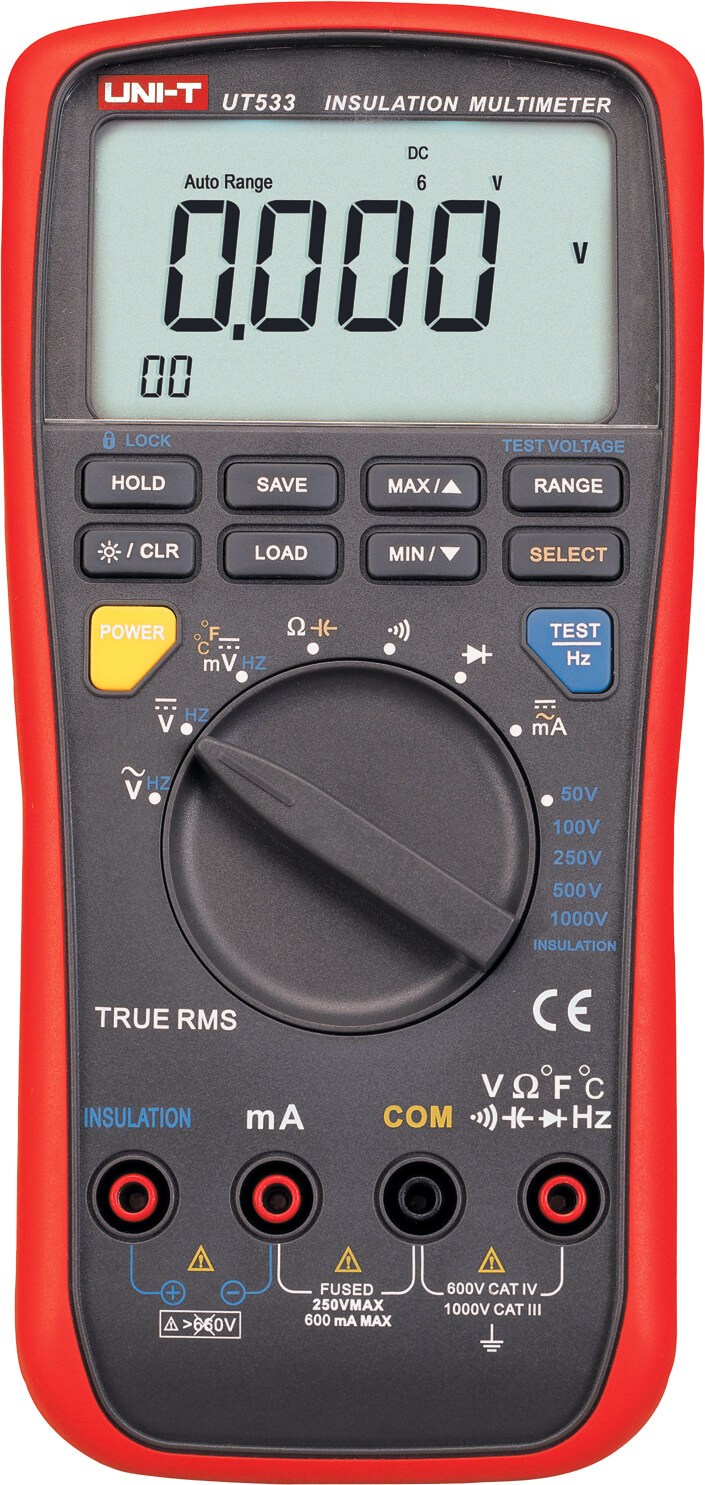

- Product num. : 202563

- EAN: 6935750553305

- Manufacturer: UNI-T

- Manufacturer number: UT533

-

Show more

- DC Voltage: 60mV/600mV/6V/60V/600V/1000V ±(0.3%+4)

- AC Voltage: 6V/60V/600V/1000V ±(1%+3)

- DC Current: 60mA/600mA ±(1.0%+2)

- AC Current: 60mA/600mA ±(1.5%+2)

- Rating: CAT IV 600V / CAT III 1000V

- Display Count: 6000

- True RMS: ✓

- Auto Range: ✓

-

From 1€167.23*

-

From 5€158.87*

-

From 10€153.85*

-

From 25€146.32*

Available, delivery time: 1-3 days

Insulation measuring devices: Precise measuring instruments for electrical safety

Introduction to the world of insulation measuring devices

Insulation measuring devices are indispensable tools for checking electrical insulation in various applications and industries. They are mainly used to ensure the safety and functionality of electrical systems. From commercial to industrial environments, these precise instruments play a crucial role in preventing short circuits and electrical accidents.

By measuring the resistance between different parts of an electrical system, insulation measurement devices help to identify potential weak points and failures. This is particularly important in critical infrastructures where electrical safety is paramount.

Application areas of insulation measuring devices

Insulation measuring devices are used in a wide range of industries. In electrical installations, they are used to check the insulation of cables and wires. This ensures that the installations meet the required safety standards and function reliably over a long period of time.

Insulation measuring devices are also irreplaceable in the maintenance and servicing of machines and systems. They help to detect damage at an early stage and thus minimize expensive downtimes. They are used as standard in industries such as power generation and distribution, mechanical engineering and telecommunications.

Functionality and measuring principles of insulation measuring devices

The basic function of an insulation measuring device is to apply a test voltage to an electrical system and measure the resulting resistance. High-quality devices can measure resistances in the megaohm range, which gives them high precision and reliability.

There are different types of insulation measuring devices that use different measurement methods depending on the application. Some work with a constant test voltage, while others vary the test voltage to obtain more comprehensive data. Modern devices are often featured with additional software that analyzes and interprets the measurement data.

Importance of the regular insulation test

Regular insulation tests are an essential part of a proactive maintenance program. They help to extend the service life of electrical systems and increase their operational reliability. By detecting insulation problems at an early stage, costly repairs and downtime can be avoided.

In many industries, regular testing is required by law. For example, electrical engineering standards in many countries require regular insulation measurements to ensure the safe operation of electrical systems. These regulations serve to protect people and property.

Important features when buying an insulation measuring device

Different factors should be taken into account when purchasing an insulation measuring device. The measuring accuracy and measuring range are crucial criteria to ensure that the device meets the specific requirements. User-friendliness, such as a clear display and simple operation, is also important.

Additional functions such as storage of measurement results, data export and integration into existing systems can contribute significantly to the efficiency of testing processes. Robustness and reliability are also key features, especially in industrial environments where the devices are often exposed to harsh conditions.

Technological advances in insulation measuring devices

As technology has advanced, insulation measuring devices have also evolved. Modern devices offer a variety of functions that complement and improve traditional measurement methods. These include wireless communication and a computer interface.

These innovations help to make the testing process more efficient and precise. For example, users can monitor and evaluate measurement data in real time, even remotely. These developments not only improve safety, but also productivity.

Environmental and safety aspects

Insulation measuring devices must comply with strict environmental and safety standards. High-quality devices are rigorously tested to ensure that they can work reliably in different environments. Safety features such as overvoltage protection and automatic shutdown also play an important role.

Compliance with environmental standards, such as RoHS (Restriction of Hazardous Substances), ensures that the devices are environmentally friendly and do not contain any harmful substances. This is particularly important in an increasingly environmentally conscious market.